Description

White Cosmetics Pulp Trays

White Color Cosmetic Custom ECO Pulp Packaging Trays 100% Compostable eco-friendly molded pulp packaging. Waterproof, shock-proof, anti-cushioniong. Smooth surface, good quality, luxury inner tray packaging solutions.

The use of molded pulp has never been more prevalent and popular than it is today. This packaging solution is the best packaging material choice for thousands of product applications.

Inquiry E-mail: info@custompulp.com

Our Pulp Trays are Certified by EU SVHC, EU ROHS of Safety Materials.

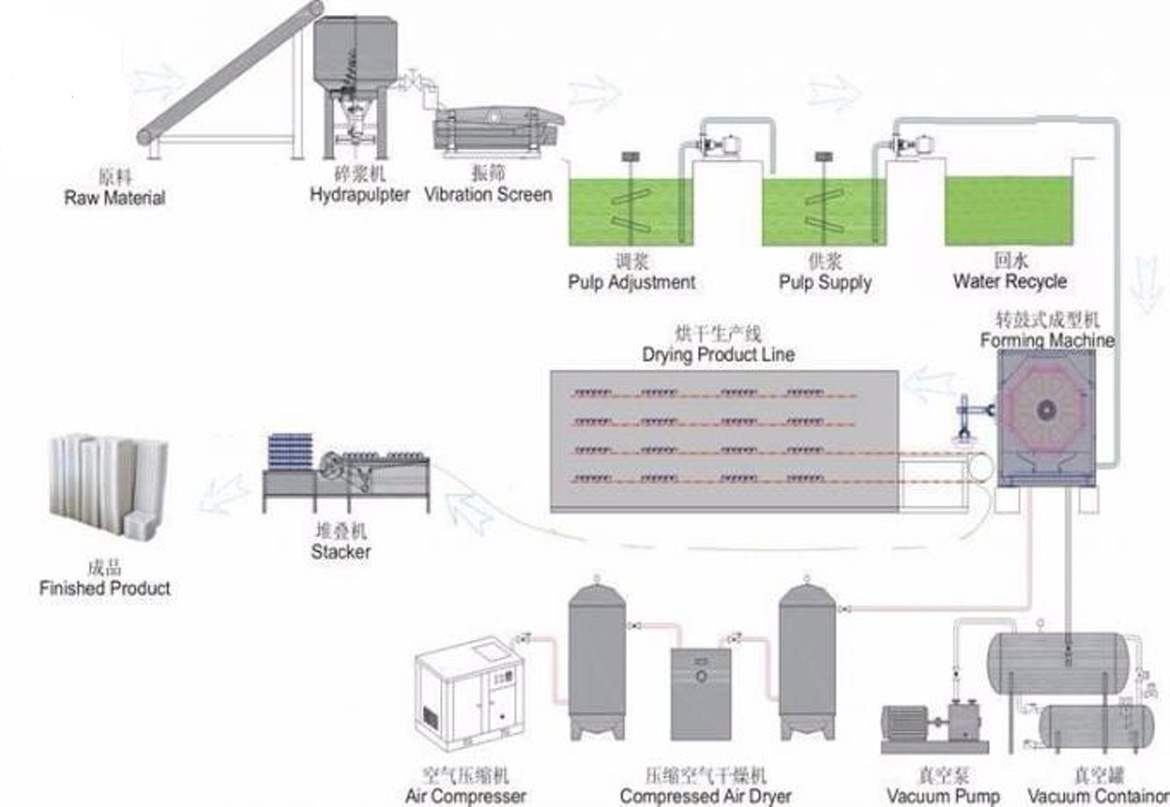

Molded pulp packaging, synonymously known as Molded Pulp Tray Packaging, is made up of a fibrous mixture of materials. The combination of green reusable trash like recycled paper, cardboard, old corrugated carton (OCC), and even other natural fibers (bagasse, bamboo, or even wheat straw) becomes compiled into the eco-friendly packaging.

However, much like the basis of the material used that’s reprocessed into the packaging, the result of this combined concoction will ultimately determines the color, surface properties, and even the resistance of the packaging. Hereof, it’s also safe to say that the molded pulp packaging also known as ‘eco-friendly packaging’, as there are grade variants towards its hardness. And much like the growing importance of sustainability, molded pulp packaging is now serving as a better, alternative option more lucrative when compared to other packaging. Because unlike plastic and even polystyrene (EPS), the fibers in pulp packaging are biodegradable.

Inquiry to get Price E-mail: info@custompulp.com

There are a wide variety of usage towards the pulp trays of eco-friendly packaging in Packaging markets still, and even beyond the mere stating of the food and cosmetic use. The usage of single use plastic is gradually making its shift for a sustainable alternative like the pulp mold.

Furthermore, this eco-friendly packaging has protective barriers to secure electronic products such as computers, smartphones, and other technology-related accessories, the pulp tray packaging has become well represented in retail and premium stores with aesthetics and printing effects on them.

Molded pulp is an environmentally friendly, sustainable, and innovative solution to your product protection and packaging needs. Making the smart choice to use molded pulp packaging not only benefits the environment, but your business will reap the rewards of financial savings. The lightweight and stackable material allows you to save space, time, and costs associated with manufacturing, storing, and shipping your products, but still provides the necessary protection for your products as they move through your logistics network. Here at Custom Pulp Packaging, custom pulp specializes in designing and manufacturing custom molded pulp packaging for use with various industrial products.

A package that is presented neatly, cleanly, and has the product securely in place will let the consumer know that your brand places value on creating a high-quality product. Therefore, the customer will be able to trust that you can provide a great product and will be more likely to purchase in the future.

An unboxing experience that does not require a struggle will create a pleasant first interaction for the customer.

If the packaging is difficult to open or seemingly poorly put together, it can make the customer feel frustrated and have them feel that the brand did not keep the end-user in mind. To create a neatly presented package that has an intuitive unboxing design, brands can use: Modular inserts Paper trays A structured box with folds that easily open.

Inquiry to get Price E-mail: info@custompulp.com

Benefits of Using Custom Molded Pulp Packaging

1. Pulp packaging has excellent protection properties with water resistant to protect the product.

2. This eco-friendly packaging is manufactured with 100% raw materials mainly from Fiber Pulps.

3. Final outcome of the molded pulp packaging results in 100% recyclability.

4. All molded pulp packaging is customizable to any preferred design and shapes based on the requirement needed.

5. All scraps of this eco friendly packaging from manufacturing process are returned into the pulp slurry to avoid any wastage.

6. This wrapping is designed to be able to stack and reduce cost in storage and shipping, resulting in saving transportation time.

Best Plus Custom Pulp Co., Ltd has always focused on the design, development and production of environmentally friendly paper trays, paper tray packaging, pulp molding, pulp packaging, and pulp crafts introduction and promotion. Our Paper Pulp Packaging products mainly include custom pulp Packaging: Dry Pressing Pulp Trays, Wet Pressing Pulp Trays, Color Pulp Trays, Cosmetics Packaging Trays, Industrial Packaging Trays, Electronics Trays, Medical Packaging Trays, Color Cosmetics Trays, Food Pack Trays, pulp molding Trays, electrical paper holder and other paper holder products custom made. Color Custom Trays can be done for Black, White, Brown, Orange, Green, Grey, Red, Blue, Purple, Pink, Yellow, and others.

With the need for cost-effective but innovative packaging design to reduce environmental impact, custom-pulp is certain that molded pulp can be adapted to your needs. If you need to find a new packaging solution for your paper pulp packaging products, contact CUSTOM PULP to help you design and develop the molded pulp packaging that will work for you and your products.

Inquiry E-mail: info@custompulp.com

How do you Order?

1. Analyse

After our initial conversation, our Team may ask for drawings, documents, specifications and/or products.

2. Design

Using your input and drawings, documents, specifications and/or products, concepts emerge, after you confirm to work with us.

3. Prototyping

Generate sample trays for evaluation, Discuss and test. If changes are needed, additional Samples can be generated unless both parties decide Implement these revisions in the production tools.

4. Tools and Manufacturing

Production Trays are manufactured and shipped within a few days after receiving purchase orders.

Reviews

There are no reviews yet.